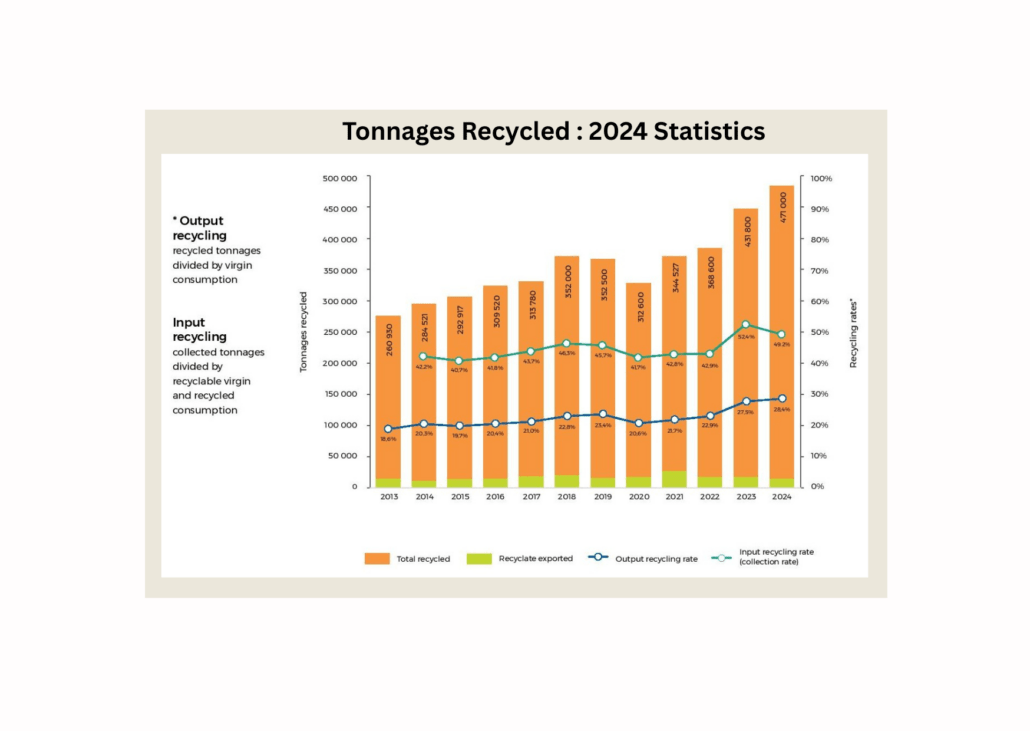

It’s estimated that South Africans produce approximately 122 million tonnes of waste (building rubble, mining sludge, organic waste garden cuttings, packaging, etc) each year with around 10% of that waste recycled. The good news is that the country is making positive strides in terms of recycling more of its plastic waste. In 2023, for example, SA recycled over 431,800 tonnes of plastic waste, up from 260,930 in 2013.

Anton Hanekom, executive director at Plastics SA, had the following good news for South Africans:

‘SA has made significant progress in developing mechanical and advance recycling technologies, phasing out non-recyclable products and promoting design for circularity. South Africa has also implemented Extended Producer Responsibility (EPR) regulations that place accountability on producers for the lifecycle of their products.

It has established itself as a global leader in mechanical plastics recycling, particularly where thin polyethylene films and contaminated post-consumer plastics are concerned.

A key driver of this progress is the implementation of Extended Producer Responsibility (EPR) regulations. Founded on the “polluter-pays” principle, the EPR system holds producers accountable for the entire lifecycle of their products. This policy has become a key pillar of South Africa’s recycling strategy, driving investment in recycling infrastructure, encouraging innovation in product design and strengthening collaboration between industry, government and consumers.

SA has already launched several targeted initiatives, including projects to promote the reuse of plastic packaging, improved sorting and beneficiation of all packaging, accredited training for waste pickers and river catchment programmes aimed at removing plastic waste from the environment to curb pollution.

Between 2014 and 2024, the use of recyclate or recycled plastic material, increased by more than 67%. South Africa’s per capita plastic consumption remains relatively low and stable at around 27 kg per person per year, well below the global average. Despite significant challenges in waste management infrastructure, with 39% of the population lacking access to formal waste collection, recycling continues to grow. In fact, South Africa recycled and reused 458,000 tons of plastic waste in new products, achieving a recycling output rate of 28.4%, more than double the world average! These measures show that we are not waiting for a global treaty to take action.

Of all the locally manufactured plastics packaging, 46% has been successfully recycled—turned back into raw materials used in the manufacturing of new products. Importantly, brand owners and retailers are increasingly incorporating recycled content into packaging applications, with a particularly strong uptake of recycled material in the production of carrier bags.

Despite the recent setback at the Intergovernmental Negotiating Committee (INC-5.2) session in Geneva where governments failed to reach agreement on securing a legally binding global treaty on plastic pollution, momentum continues in South Africa.

SA is currently hosting the G20 Environment and Climate Sustainability Ministerial meeting in Cape Town (16-17 October), where plastics, waste and chemicals are key items on the agenda. This event will provide another platform to press for solutions and strengthen international cooperation to end plastic pollution.

The local plastics industry, though small in global terms, is the largest of its kind in Sub-Saharan Africa. With 295 recycling operations recorded in the country, the industry has become a significant source of employment and economic value. It’s estimated that the waste collection industry sustains 95,900 informal jobs, contributing over R4.7 billion to the informal economy.’

Hanekom says a global plastics treaty remains the best opportunity SA has to coordinate action, accelerate the circular economy and protect the environment for future generations. The Plastics industry, including Plastics SA, is ready to contribute expertise and innovation to ensure that when negotiations resume, they succeed. The stakes are simply too high to allow further delay!

This article recently featured in Business Day Insight – Recycling